Different values of cleanrooms

The capacity of a Fab is directly related to the cleanroom size. But not only the area matters, also the type of cleanroom result in relevant space efficiency differences.

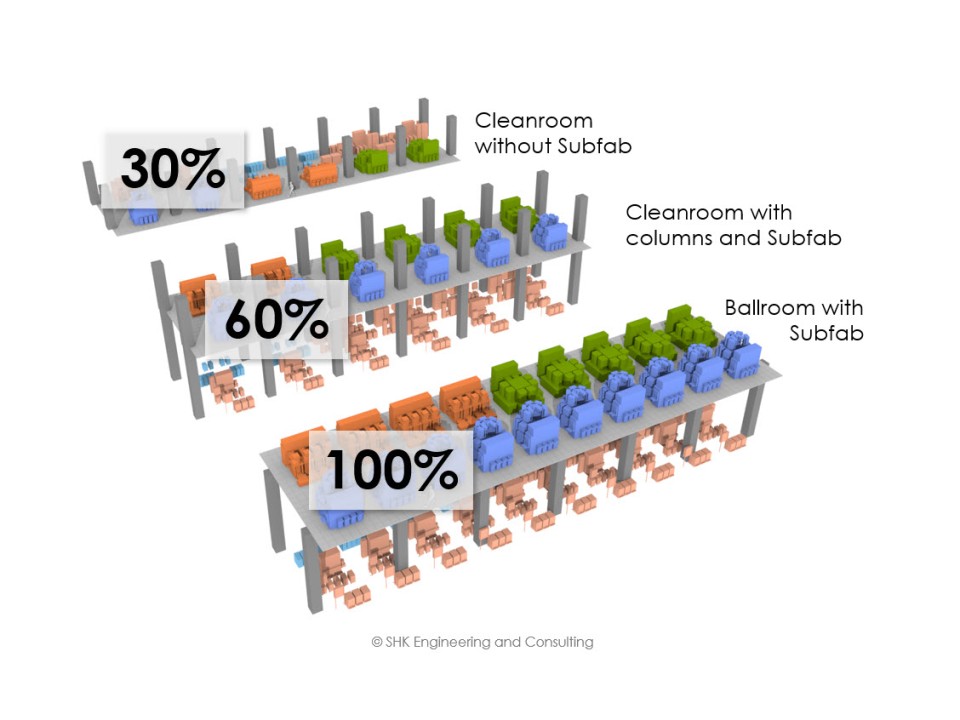

See above, what happen if you look closer on a dry-etch space with about 5500 ft²/500 m². In this area 19 larger chamber equipments can be placed well in a ballroom with free Subfab.

The same cleanroom size, but with columns every 24’/7,2m, the situation is very different. Two of these typical etch equipments do not fit between the columns, so only one equipment between two columns can be placed. This result in space for only 12 equipments or an space efficiency of only 60% in comparison to the ballroom.

Without Subfab and with columns, the area efficiency, in the same cleanroom size, goes down to only 30% as Sub Equipment need to be installed on the cleanroom level.

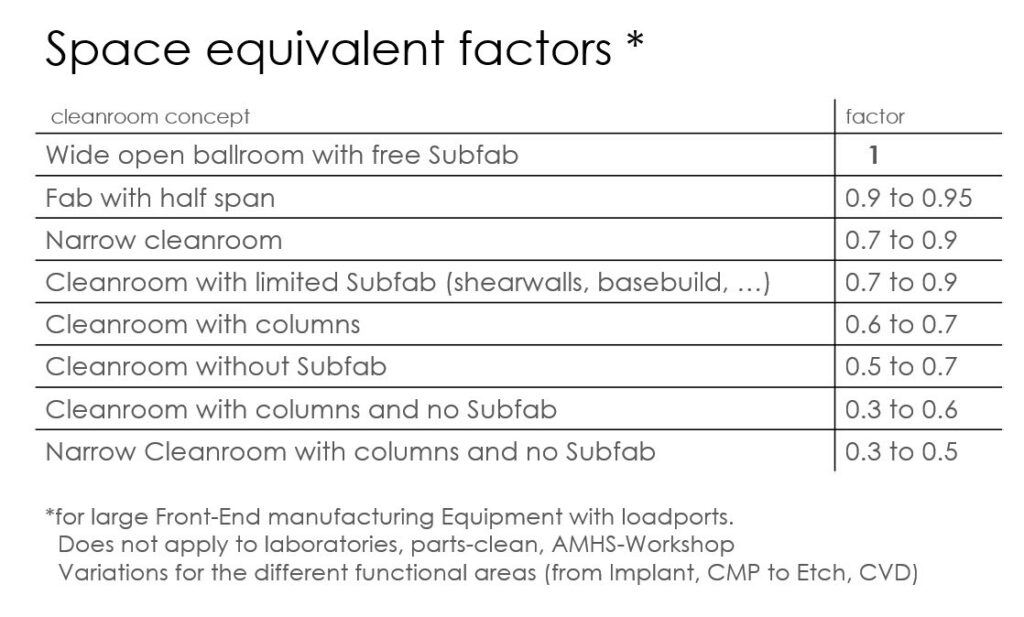

SHK reviewed different cleanroom concepts regarding space efficiency of various projects we have been involved. There are quite a number of more space restrictions for 300mm Fab cleanrooms beside the topics mentioned above: In narrow buildings the efficiency goes down due to the higher ratio of move-in aisles/equipment areas. Columns result also in constraints for a clear and straight AMHS layout. Facility installations in the Subfab limit in consequence usable equipment space. And some more. One result of our Fab design research project are conceptual design factors for the different cleanroom types.

Imagine you could build a Fab smaller because the clean room can be used only some percent more efficiently. With the high investments in building and infrastructure this could easily result in remarkable savings – up to the value of an EUV cluster. Or the other way around: More high value manufacturing space for the same money would be an even better benefit for a new Fab project.

Unfortunately, to realize high space efficiency, knowledge alone is not enough. Without continuous follow up throughout the entire design and construction phase many not-equipment-related installations will grow into manufacturing space before the first equipment arrives.

In any case: The one who consider cleanroom efficiency in conceptual fab design will be in the lead and the more Giga, the easier it will be to achieve high space efficiency.

Comment on LinkedIn