Three topics, one solution

First topic: Gas detection limitations because of dilution with exhaust air

Gas detectors connected to equipment gas boxes are limited in their detection reliability due to the fact that the high extracted exhaust volume dilutes leaks by a factor of some hundred times or more.

An example from one of our projects: A leak in the gasbox from a doped-poly furnace, caused by a loosened VCR connection, was not detected. We reconstructed the event and fed calibration gas into the gas box after calibrating the gas detector and checking its operation. It was confirmed what we had already expected: Even a medium leak could not be detected by the gas detector, because the dilution in the exhaust air reduced the proportion of the gas to be detected below the detection limit of the sensor.

It is a known problem: Reducing the exhaust air flow increases the detection sensitivity but at the same time it reduces the safety in case of a larger leak.

Second topic: Space management issues because of large exhaust pipes

A large part of the building volume or building height is needed due to the large diameters of exhaust piping systems. Any reduction of exhaust piping diameters would help the space management and could even allow to reduce the building volume and height.

Third topic: All exhausted air must be replaced with make-up air

In order to maintain the positive pressure in the clean room, each cubic meter of extracted exhaust air must be replaced by an costly processed cubic meter of fresh air. Make up air units are expensive, have high operation costs and need a lot of space. Reducing the size of these units would result in measurable savings.

One solution

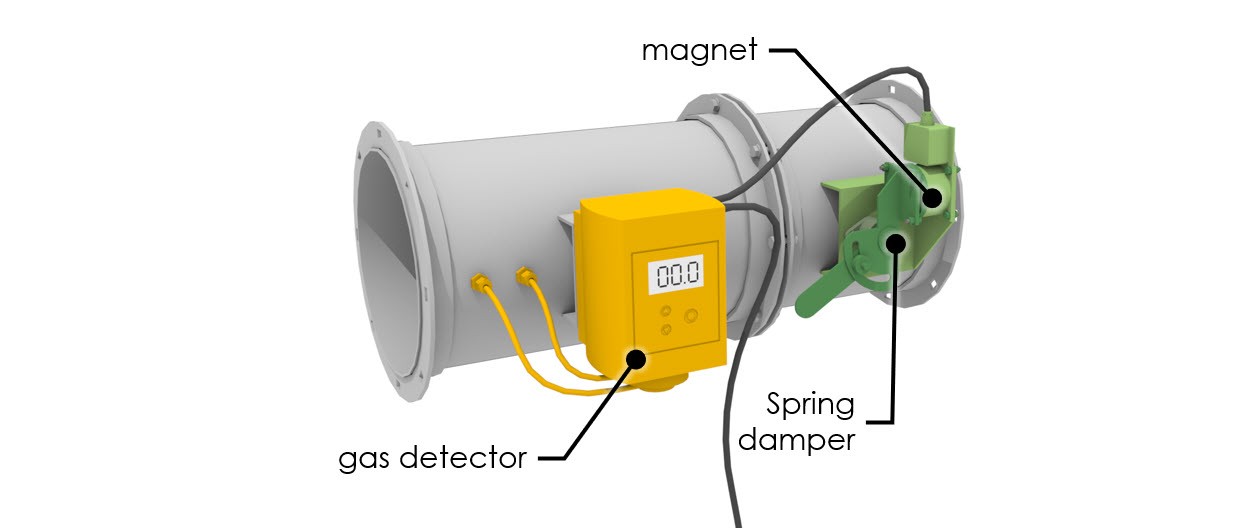

SHK has developed a patented unit as solution for all three topics. The unit is installed in the hook-up line of the gas box. A safety magnet, similar to those used to hold fire doors, holds the exhaust damper in a more closed position. The small exhaust volume allows to detect even very small leaks. As soon as a leakage is detected, the magnet is released and the spring opens the damper completely.

This unit introduced in all exhaust lines from gasboxes and valve manifold boxes will increase safety. As the overall exhaust volume is reduced, exhaust pipes and make up air handling units can be sized smaller at the same time. The resulting savings make sure that the system pays off within a short period of time.